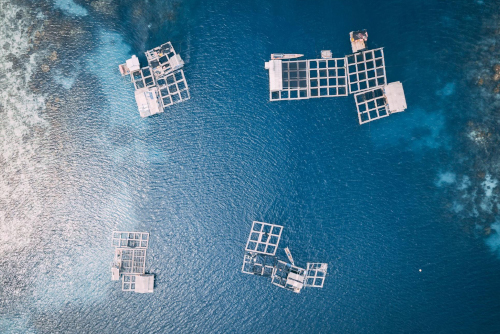

Aquaculture, already one of the world’s fastest-growing agri-food sectors, has the potential for further expansion in providing high-quality and healthy fish products to the world’s population.

With a global capture production of approximately 90 million tonnes, aquaculture production has maintained consistent annual growth, reaching a global production of approximately 70 million tonnes in 2013.

In aquaculture production, a greater emphasis on sustainability, consumer demands, food safety, and cost-effectiveness necessitates the continuous development of new production technologies.

In general, aquaculture production has an impact on the environment, but cutting-edge recirculation methods reduce this impact significantly when compared to traditional methods of fish farming. As a result, recirculation systems provide two immediate benefits: cost-effectiveness and reduced environmental impact.

Recirculation aquaculture is an approach of farming fish or even other aquatic organisms that utilize the water used in the method. The technology is based on the use of mechanical and biological filters, and it can be applied to any aquaculture species such as fish, shrimp, and clams.

However, recirculation technology is most commonly used in fish culture.

Recirculation has become more and more popular and widespread in the fish farming sector, with new installations in units ranging from huge plants producing many tonnes of fish each year for ingestion to small complicated techniques used for restocking or saving threatened animals.

Awareness, good domestication, persistence, and, at points of time, steel nerves are required in aquaculture. Transitioning from traditional fish farming to recirculation streamlines many objects, but it also necessitates the acquisition of newer and better skills.

Let’s now discuss the principles of recirculationg system in aquaculture.

In fish culture units, recirculating aquaculture systems are meant to reduce or eliminate the need for water exchange and flushing.

Commercial aquaculture hatcheries, holding tanks, aquaria systems, as well as small-scale aquaculture operations, can all benefit from these systems. When there is a specific need to limit water replacement, preserve water quality conditions that differ from the source water, or compensate for an insufficient water supply, water is often recirculated.

There are numerous recirculating system designs, but the most will operate well if they achieve the following goals:

These activities can be carried out by a single composite unit, such as a bulk filter me

dia, or by numerous interconnected components in larger systems.

The only workable approach for decomposing dissolved waste materials from fish tank access point water has conclusively been demonstrated to be mechanical filtration.

A great majority of recirculated fish farms presently screen the tank exhaust water through one micro screen equipped with filter brushes varying from 40 to 100 microns. The drum filter seems to be the most commonly used type of micro screen, and it’s part of the scheme that particles are removed gently.

The drum filter’s function is as follows:

The following are the benefits of micro screen filtration:

Ammonia (NH3) excreted across the gill membranes of fishes is the primary form in which fish and other aquatic organisms excrete nitrogenous wastes. Undigested nitrogen fractions in urine, solid wastes and excess feed are also sources of ammonia.

Ammonia is toxic to fish and can cause sublethal stress at concentrations as low as 0.05 mg/l ammonia nitrogen (NH3 -N), resulting in poor growth and disease resistance.

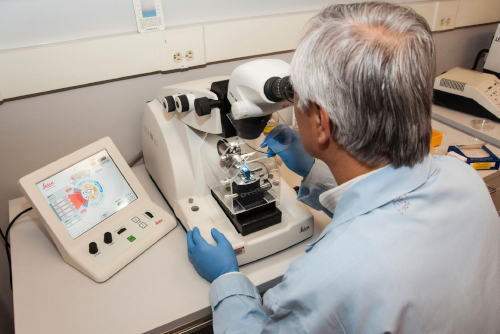

A relatively large space is provided for microbes that biochemically oxidize ammonia to fairly benign nitrate in the recirculating water system that keeps ammonia levels under control. Bacterial nitrification is a two-step process that converts ammonia to nitrite and then oxidizes the nitrite to nitrate.

Bio Foam Filter is the most widely used biological filtration method and type. They all have one thing in common: they all use natural, biological processes to convert toxic ammonia and ammonium fish waste into less hazardous nitrates or nitrogen gases.

Because nitrate is toxic to fish at low concentrations, both reactions must occur for biofiltration to be successful. The bacteria that cause these reactions are common in soil and water environments and can be easily inoculated into biofilters made from natural sources or with material from existing aquaculture filters.

Before stocking fish, a biofilter is typically conditioned for several weeks by adding ammonia and monitoring its breakdown to ensure bacterial populations are sufficient to remove ammonia and nitrite at the rates required during operation. Oyster shells, gravel, nylon netting, plastic rings, and sponge foam pads are just a few illustrations of biofilter media.

Ceramic filter media are biological media with a large surface area for beneficial bacteria to grow and live on. The bacteria on your ceramic rings are required to complete your tank’s Nitrogen Cycle, which converts harmful ammonia and nitrite to less harmful nitrate.

When constructing biofilters, the top issues should be a greater surface area for the growth of bacteria, high oxygen concentration levels, homogeneous water flow through the aquaculture filter system, adequate blank room to help stop clogging, and appropriate sizing to guarantee appropriate ammonia removal capability.

Estimating the appropriate size of a biofilter is challenging since filter surface area, fish mass, and flow of water are all significant considerations. A tank-to-biofilter volume fraction of 3:1 is usually sufficient.

Water for recirculation aquaculture systems must preferably be disease-free or germ-free before actually accessing the network. Water from a borehole, well, or similar source is usually preferable to water from a river, lake, or sea.

If an intake water treatment system is required, it will typically include a sand filter for microfiltration and a UV sterilizer machine or ozone system for disinfection.

Guess it depends on the saturation point of oxygen in the atmosphere, the water aeration procedure, which is about the same physical process as degassing or stripping, will add some oxygen to the water through a quick transaction seen between gases in the water as well as the gases in the air. In water, the oxygen homeostasis is completely saturated.

The oxygen content of the water is controlled when it goes through the fish tanks, generally to 70%, and it is even farther lowered in the biofilter.

However, higher than 100% oxygen saturation in the inlet water to the fish monitoring system is often preferred to have enough oxygen available for high and stable fish growth. Saturation levels above 100% necessitate the use of a pure oxygen system.

Pure oxygen is frequently delivered in tanks as liquid oxygen, but it can also be produced on the farm using an oxygen generator. There are several methods for producing super-saturated water with oxygen contents ranging from 200 to 300 percent. The most prevalently used oxygen processes are high-pressure oxygen cone processes or low-head oxygen structures, such as oxygen portals.

The fundamental principle remains the same. Water and pure oxygen are blended under pressure, and the oxygen is compelled into the water.

The pressure in the oxygen cone is achieved by using a pump, which generates significant pressure of about 1.4 bar in the cone. Pumping pressurized water into the oxygen cone due to the high consumption of electricity.

On the oxygen platform, the pressure is much relatively low, usually around 0.1 bar, and water is simply psyched through the box, blending water and oxygen. The oxygen cone solution uses only a portion of the circulating water for oxygen enrichment, whereas the oxygen platform is used for the main recirculation flow, often in conjunction with the overall pumping of water around the system.

Whatever method is used, the process should be monitored using oxygen measurement. The best way to accomplish this is to have the oxygen probe measure after the oxygenation system at normal atmospheric pressure, such as in a measurement chamber provided by the supplier. Because the probe will need to be wiped clean and calibrated on a regular basis, this makes the measurement easier than if it were made under pressure.

Maintaining an optimal water temperature in the culture system is critical because the fish growth rate is directly related to water temperature. Using the intake of water to regulate the temperature from day to day is a relatively simple method.

Heat will gradually accumulate in the water in an indoor recirculation system because the energy in the form of heat is released from the fish metabolism and bacterial activity in the biofilter. Heat will be accumulated as a result of friction in the pumps and the use of other installations. As a result, high temperatures in the system are frequently a problem in an intensive recirculation system.

Temperature can be easily controlled by adjusting the amount of cool fresh intake water into the system. If the use of intake water for cooling is limited, a heat pump can be used. The heat pump will use the energy that would otherwise be lost in the discharge water or the air leaving the farm. The energy is then used to cool the farm’s circulating water.

A similar method of lowering heating/cooling costs is to recover energy through the use of a heat exchanger.

This is accomplished by passing both streams through a heat exchanger, where the warm outlet water loses energy and heats up the cold intake water without mixing the two streams. A heat exchanger for air can also be installed on the ventilation system, utilizing energy from the outgoing air and transferring it to the in-going air, significantly reducing the need for heating.

Heating the water may be necessary for cold climates. The heat can come from any source, such as an oil or gas boiler, and is connected to a heat exchanger to heat the recirculated water, regardless of the energy source. Heat pumps are an environmentally friendly heating solution that can use energy from the ocean, a river, a well, or the sun.

A recirculation system is both expensive to build and maintain. Markets for fish are competitive, and in order to make a profit, production must be efficient. Choosing the right species to produce and building a well-functioning system is thus critical. Essentially, the goal is to sell the fish at a high price while keeping production costs as low as possible.

RAS conserves water by constantly reusing it. Furthermore, the total amount of water required in the system, to begin with, is only 20% of that required incomparable open culture systems. RAS is a promising solution to water use conflicts, water quality, and waste disposal, particularly in areas where there are already water shortages.

Recirculation Aquatic System is similar to the broiler house or swine barn methods used in chicken and pork production in that it allows for much more intensive production on the same amount of space.

RAS can produce over 100,000 pounds of fish in a 5,000 square foot building, whereas open culture systems require 870,000 square feet (20 acres) of space to produce the same amount of fish.

Fish rearing in confined spaces has the potential to revolutionize fish farming in the same way that these methods have transformed chicken and pork farming, which is obviously beneficial to farmers’ profits.

RAS requires fewer inputs than conventional aquaculture and is also carried out away from large bodies of water. This means that the ecological impact of aquaculture activities on wild aquatic flora and fauna is negligible. RAS enables fish farming in isolation from nearby ecosystems, which is great for preserving biodiversity and mitigating the impact of waste.

Some people are good at raising funds but not at raising fish. Some people can raise fish, but not money. Projects that lack adequate startup funding are doomed to fail, either before they begin, halfway through construction, or during the first year of operation.

Remember that you need capital not only for construction but also for operating expenses and contingency funds in case of emergencies or harvest and sales delays. Not to mention the interest and return on partner investments. Short cuts and cost cuts may make sense in the initial construction, but they must be “paid back” in excess costs, retro fittings lost production, and staff morale while attempting to manage the unmanageable.

We should, like most successful businesses, begin at the end rather than the beginning. Many people are enamored with the new shiny RAS, the animals, and the production, cost, and efficiency metrics. But what about customers, farm gate prices, and seasonal price swings? Assumptions, such as the highest and lowest sales prices, estimated market volumes, and competition, are just that: assumptions. Using erroneous farm gate prices to forecast profit/loss is risky.

Once the sales price and volumes are determined, the size of the RAS facility, water volumes, and production targets can be established. Too many business plans are based on a breakeven point. Breakeven is dangerously close to a loss. It is best not to proceed if there is little chance of making a profit.

Remember that even if your product is superior, you can lose customers to low-cost imports at any time. Find a species or product form that is partially immune to local and international competitors (for example, live or further processed).

RAS allows for year-round fish harvesting, increasing annual yields and boosting farmers’ profits and income security even further. It also allows farmers in colder climates to raise tropical fish that they would never be able to grow outdoors in their local climates.

A recirculating aquaculture system, like any other farming method, has drawbacks. These shortcomings may be considered limitations to varying degrees depending on the farmer’s goals and priorities.

When considering launching a RAS system, keep the following constraints in mind:

Below are key types of recirculation aquatic systems:

Home aquaria and inland commercial aquariums are types of RAS in which the water quality is carefully monitored and the fish stocking density is kept to a minimum. The goal of these systems is to display the fish rather than to produce food.

Biofilters and other forms of water treatment, on the other hand, are still used to reduce the need for water exchange and to maintain water clarity. Water must be removed regularly, just like in traditional RAS, to prevent nitrate and other toxic chemicals from building up in the system.

Because of their proximity to a large body of clean water, coastal aquariums frequently have high rates of water exchange and are not typically operated as RAS.

Aquaponics is the combination of plants and fish in a RAS. Ammonia produced by the fish is not only converted to nitrate in this system but is also removed from the water by the plants. In an aquaponics system, fish effectively fertilize the plants, resulting in a closed-looped system with very little waste and minimal inputs.

The ability to harvest and sell multiple crops is a benefit of aquaponics. There are differing opinions on the suitability and safety of RAS effluents for sustaining plant growth in aquaponics conditions.

Future conversions, or ‘upgrades,’ of operational RAS farms to semi-commercial Aquaponic ventures should not be stymied by nutrient inadequacies or nutrient safety concerns. It is encouraged to incentivize RAS farm wastes through semi-commercial aquaponics. The nutrients locked in RAS wastewater and sludge are sufficient and safe to support plant growth in aquaponics conditions.

Wasn’t that interesting? I am sure it was. The Recirculatory Aquaculture System (RAS) is a really important and useful process. This method is used for the high-density culture of various fish species while using the least amount of land and water.

Quality cannot be compromised because Recirculatory Aquaculture System is so important. As a result, a dependable manufacturer is required. Don’t forget to contact Mountain Tree for any bio filter system information. They have an incredible range of RAS trusted by millions of customers worldwide.

Leave a Reply